Supply Chain Management

Digital Supply Chain

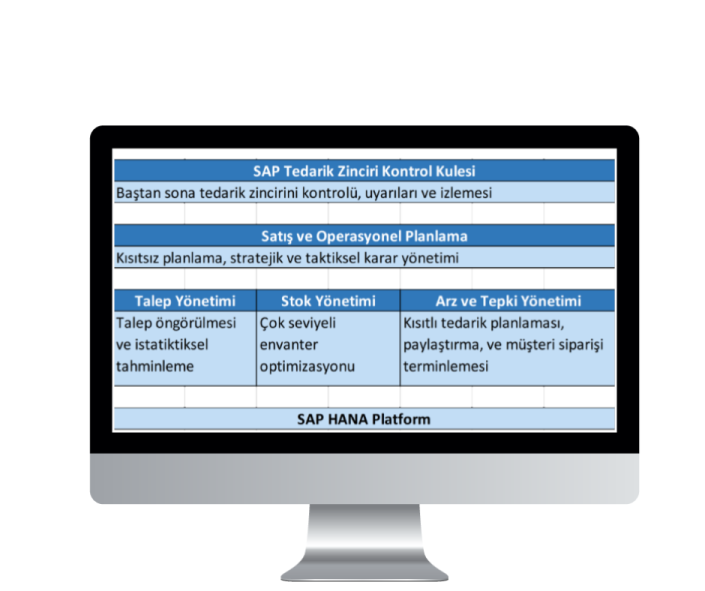

SAP Integrated Business Planning

SAP IBP maximizes the demand for new market expectations and profitability for companies and provides real-time supply chain management. In order to provide this management, it provides a unique planning environment by combining sales and operational planning, demand, stock, supply and response planning products. Thanks to Supply Chain Control Tower, it provides an environment in order to make analytic data viewed up-to-date.

SAP IBP runs on SAP Cloud with real-time management panels, planning tables that can work on Microsoft Excel, and interactive simulation and it is built on SAP HANA.

Institutions often have difficulty in setting common strategic and financial goals together. IBP solution provides operational processes for sales and operational planning, demand sensing, demand management, inventory and supply optimization, and order-based planning functions. In the supply chain structured as network, it determines alternative solution methods against problems by running heuristics and optimization. At this point, it provides as many features as the user wants, which can be used on customers, products, locations, and channels. Restricted or unrestricted models can be designed on these features.

With SAP IBP Solution;

- Sales, product, financial and operational activities can be adapted to medium and long term company strategies.

- New strategies can be identified in the financial and supply chain in order to correct adverse developments in the market or supply chain.

- In order to achieve the company goals; operational plans, which can be applied operationally and acceptable financially, can be made.

SAP IBP solution contains 5 components. Each component's contribution to the solution of IBP can be customized alone or together with other components.

SAP Supply Chain Control Tower

- Capability of determining the problems and exclusions in the supply chain instantaneously

- Capability of showing fast reaction and taking corrective actions in instantaneous developments

- Reducing supply chain costs with immediate changes within the operations implemented, ensuring that deliveries can be made in a timely manner, and lowering stock levels by taking low risk

- The response time reduction of the supply chain

Sales and Operational Planning

- It uses the following criteria in the creation of balanced cross-module.

- Stock levels,

- Production Variations

- Profitability

- Product variety

- Execution of supply-demand matching, balancing stock levels, and load calculation of used resource is possible via modeled unlimited predictions.

- It enables to achieve the target of increasing revenue and market share in the design of optimal business processes.

- Ensures that supply-demand balance is managed efficiently and financially.

Demand Management

- To improve the consistency of the short planning horizon, it deals with optimizing the planning in the medium-long period horizon.

- With motion recognition technology, it provides faster action to short-term demand variability. Manages automatic and exception-based planning process.

- It allows working in Microsoft Excel interface in manual planning methodology.

- It includes statistical prediction models for sales and operational planning.

- It works fully integrated with SAP ERP and APO. It can send and receive any kind of master data and estimated functional data.

Stock Management

- Reducing labor costs in inventory management Reducing inventory costs

- Reducing distribution costs Improving customer service levels

- It enables the management of inventory levels to meet the needs of different planning levels in the most efficient manner.

- In cases where the forecast and supply levels are incompatible, the customer ensures that the inventory targets are determined to best meet the service levels.

- Possibility to reduce production and distribution costs by following the inventory targets in each step in the supply chain.

- It helps to determine stock levels of the item in the network structure in the supply chain by using statistical processes over variables such as demand, resource, and IBP repository optimization.

Supply and Response Management

- Considering all supply chain steps, taking action according to changes in demand, source, operation and distribution steps is provided by heuristic and optimization applications.

- It is possible to determine the action to be taken by simulating restricted and unrestricted solutions against changes in customer needs.

- Models can be established through sales, inventory, capacity, procurement information and resource prioritization, supply-demand matching logics that will obtained from ERP.

- Profitability analysis and optimal result analysis can be done by reporting the differences between models.